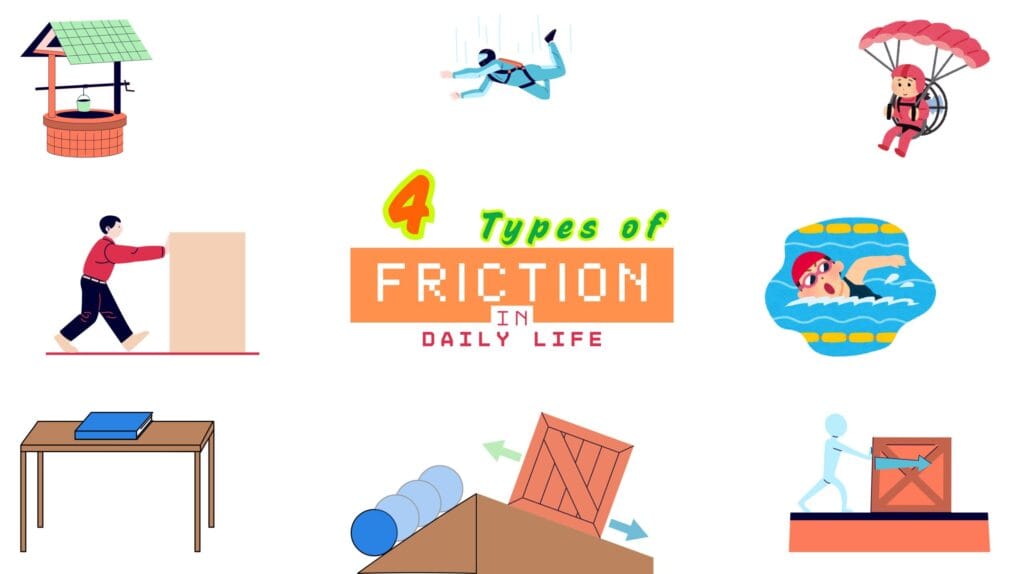

To understand 4 types of frictions – their applications, advantages, disadvantages, and the reduction methods – is beneficial for the economy and the performance of a system.

Table of Contents

Introduction

Friction is a fundamental force that influences our daily lives, from walking to the functioning of machinery. While friction has significant advantages, it also brings challenges that require creative solutions. Understanding of friction helps in devising effective strategies to leverage its benefits while minimising its drawbacks.

What is Friction?

Friction can be defined as:

“The resistance that arises when two surfaces interact physically.”

4 Types of Friction

Friction can be classified into several types, however, there are 4 main types of friction based on the nature of the surfaces and the motion involved.

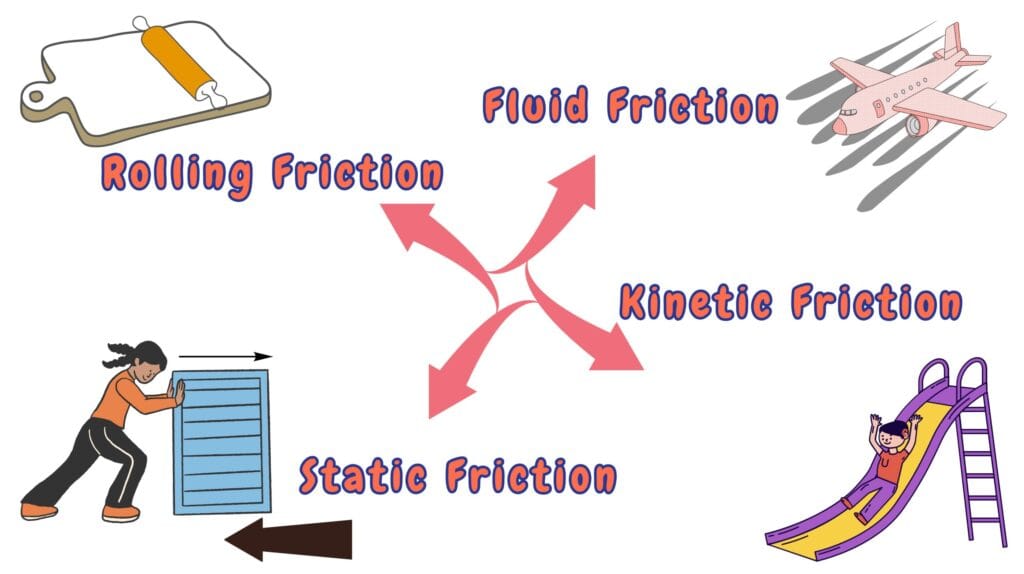

1. Static Friction

It can be defined as:

“The force that resists the initiation of motion between two stationary surfaces.”

Static friction is due to the coldwelds which are the result of microscopic interactions and surface irregularities.

Example

A box resting on a table resists the motion.

Key Feature

Static friction is generally higher than dynamic friction (sliding friction and rolling friction) because it prevents movement. As the applied force is increased, the frictional force also increases up to a certain limit called force of limiting friction.

2. Kinetic (Sliding) Friction

It can be defined as:

“The resistance encountered when one surface slides over another.”

Example

A kid enjoying a slide in an amusment park.

Key Feature

It is generally constant once motion begins. In this type of friction, there is a surface contact between two interacting objects.

3. Rolling Friction

It can be defined as:

“The resistance faced by objects rolling over a surface.”

Example

A ball rolling up and down on a slope.

Key Feature

Rolling friction is similar to sliding friction as it is prominent when an object is in motion. However, it is significantly lower than sliding friction. In this type of friction, there is either a line contact or a point contact.

4. Fluid Friction

It can be defined as,

“The resistance experienced by objects moving through a fluid (liquid or gas).”

Example

A ball fallling under gravity.

Key Feature

It depends on the shape (design) and speed of the object, and the viscosity of the fluid. Note that fluid friction is more prevalent in the field of Fluid Dynamics.

Applications of Friction

Friction plays a vital role in various real-world applications:

Transportation

Friction between tires and roads allows vehicles to move and stop effectively.

Sports

Friction helps athletes maintain grip on surfaces, improving performance.

Writing and Drawing

Pens and pencils work due to friction between their tips and paper.

Machinery

It enables the transmission of power through belts and gears.

Advantages of Friction

The advantages of friction are given below.

Enables Motion Control

Friction provides the grip needed for walking, driving, and braking.

Supports Construction and Stability

Nails, screws, and other fasteners rely on friction to stay in place.

Enhances Safety

Reduces slipping and improves handling of tools.

Facilitates Heat Generation

Useful in applications like matchstick ignition.

Disadvantages of Friction

The disadvantages of friction are given below.

Noise

Friction between components can create unpleasant sounds, especially in machinery.

Energy Loss

Friction converts kinetic energy into heat, reducing efficiency in machines.

Wear and Tear

Prolonged friction damages surfaces, leading to maintenance costs.

Hinders Motion

High friction can make it difficult to move heavy objects.

Methods to Reduce Friction

Reducing friction is essential in many scenarios to enhance efficiency and durability. Some common methods include:

Lubrication

Purpose

Applying oil, grease, or other lubricants reduces surface contact and minimizes friction.

Applications

Machinery, vehicle engines, and industrial equipment.

Using Rollers or Ball Bearings:

Purpose

Replacing sliding motion with rolling motion significantly reduces friction.

Applications

Conveyor belts, bicycles, and skateboards.

Streamlining

Purpose

Designing objects to reduce fluid resistance, such as in vehicles and aircraft.

Applications

Aerodynamics in cars and airplanes.

Polishing Surfaces

Purpose

Smoother surfaces reduce friction by decreasing surface roughness.

Applications

Tools, glass panes, and lenses.

Using Low-Friction Materials

Purpose

Certain materials, like Teflon, naturally reduce friction.

Applications

Non-stick cookware and sliding mechanisms.

Conclusion

Friction is a double-edged sword.

It is indispensable in many aspects of life. It also presents challenges that need mitigation. Whether it is lubricating machinery or streamlining vehicles, the science of friction continues to drive innovation in engineering and technology.

Frequently Asked Questions (FAQs)

What is friction, and why is it important?

Friction is the resistance force that occurs when two surfaces interact. It is essential for enabling motion control, such as walking, driving, and braking, and it plays a critical role in various mechanical and everyday applications.

What are the 4 types of friction?

The main types of friction are:

- Static Friction: Resistance before motion begins.

- Kinetic (Sliding) Friction: Resistance during sliding motion.

- Rolling Friction: Resistance in rolling objects.

- Fluid Friction: Resistance experienced by objects moving through liquids or gases.

How is static friction different from kinetic friction?

Static friction prevents motion from starting and is usually higher than kinetic friction. Kinetic friction occurs once an object is in motion and generally remains constant during the movement.

What are the advantages of friction?

Friction enables motion control, supports stability in structures, enhances safety by preventing slipping, and facilitates heat generation for useful purposes like lighting matches.

What are the disadvantages of friction?

Friction can lead to energy loss (as heat), wear and tear of materials, noise in machinery, and hindered motion, especially in heavy objects.

How does lubrication help in reducing friction?

Lubricants like oil or grease form a thin layer between surfaces, minimising direct contact and reducing friction, thereby improving efficiency and reducing wear.

Why is rolling friction less than sliding friction?

Rolling friction involves a smaller contact area (point or line contact) compared to sliding friction, which has surface contact, resulting in significantly less resistance.

How does streamlining reduce fluid friction?

Streamlining reduces resistance by improving the shape of objects, allowing them to move smoothly through a fluid (air or water) with minimal drag.

What are some real-world applications of friction?

Friction is essential for:

- Driving and braking in vehicles.

- Writing and drawing with pens or pencils.

- Power transmission in machinery.

- Ensuring grip in sports activities.

Can friction be entirely eliminated?

Friction cannot be completely eliminated as some level of resistance always exists due to molecular interactions. However, it can be significantly reduced through techniques like lubrication, using low-friction materials, and designing smoother surfaces.