Understanding thermal expansion in solids, liquids, and gases is important because it affects many aspects of our daily lives. For instance, materials like metal, concrete, and even plastic can either expand or contract when exposed to temperature variations.

Table of Contents

Introduction

When a material is heated, it either expands or contracts. This expansion or contraction of a material is called thermal expansion and is a natural phenomenon. It happens because the particles inside the material move faster and spread out or slow down and come closer together.

It is important to take into account the expansion and contraction of the material, as it can lead to problems such as:

- structural damage

- parts not fitting together properly

By knowing how different materials respond to heating, we can design and build structures that can bear temperature changes without causing damage.

Thermal Expansion in Solids, Liquids, and Gases

When heated, solids, liquids, and gases all go through expansion, however, they behave differently.

Solids

Solids, typically, show expansion in one direction, but they can also undergo expansion in three dimensions. For example,

- Pipelines

- Metal rods

- Railroad tracks

- Concrete or Steel Bridges

Liquids

Liquids also expand when heated, but they expand evenly in all directions. For example,

- Lava

- Cooking oil

- Water Heated in a Pot

- Mercury Thermometers

Gases

Gases also expand when exposed to heating, but their expansion is more noticeable compared to solids and liquids. For example,

- Car tires

- Hot air balloons

- Inflatable Balloons

Thermal Expansion (Definition)

It can be defined as “the natural tendency of a matter to change its shape, area, and/or volume when exposed to a change in temperature.”

Why does a material expand?

The heating of a material causes its particles to gain energy and move more forcefully, causing the material to expand. Conversely, cooling a material causes its particles to lose energy and move slower, causing the material to contract.

Types of Thermal Expansion

There are two important types of expansion,

- Linear Thermal Expansion

- Volume Thermal Expansion

Linear Thermal Expansion

It can be defined as, “an increase in length of a material along a single dimension under the influence of change in temperature.”

Examples

It is normally observed in solids. Expansion joints in structures such as bridges and railways are used to accommodate the changes in length due to temperature variations.

Mathematical Formulation

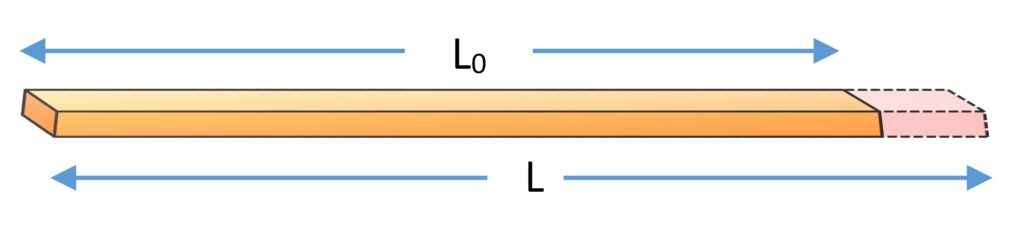

Consider a metallic rod that is undergoing expansion because of heating as shown in the figure. The particles of the rod gain energy and move more rapidly, causing the rod to elongate when exposed to heating. Let us assume that:

Before heating,

Initial Length of Rod = L0

Initial Temperature of Rod = T0

After heating,

Final Length of Rod = L

Final Temperature of Rod = T

When the rod undergoes expansion,

Change in Length = ∆L = L – L0

Change in Temperature = ∆T = T – T0

It has been observed experimentally that,

L ∝ L0

L ∝ ∆T

Combining the two proportionalities, we get,

∆L ∝ L0 ∆T

∆L = (constant) L0 ∆T

The following formula let us find the linear expansion (∆L) of a material as given below,

∆L = α L0 ∆T

Here, α is the proportionality constant. It is called as coefficient of expansion (or more accurately coefficient of linear expansion).

α = coefficient of linear expansion

Interpretation

- This formula shows that the length variation (∆L) is directly proportional to the original length (L0) and the temperature variation (∆T).

- The coefficient of linear expansion (α) quantifies variation in the length of a material per degree rise or fall in temperature.

Volume Thermal Expansion

It can be defined as, “an increase in volume of a material along a single 3-dimensional space under the influence of change in temperature.”

Examples

This type of expansion is normally observed in liquids and gases (fluids). The expansion of a fluid upon heating can be seen in a variety of applications, including thermometer design and water heater construction.

Mathematical Formulation

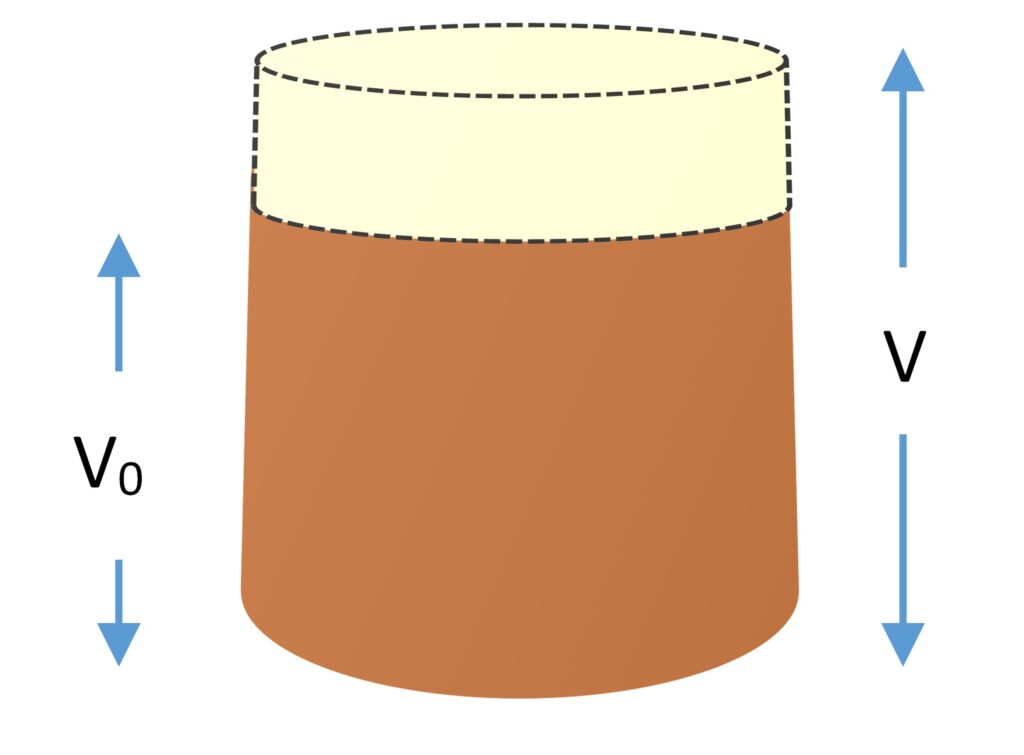

Consider a fluid that is undergoing expansion because of heating as shown in the figure. The particles of the fluid gain energy and move more rapidly, causing the fluid to rise when exposed to heating. Let us assume that:

Before heating,

Initial Volume of Fluid = V0

Initial Temperature of Fluid = T0

After heating,

Final Volume of Fluid = L

Final Temperature of Fluid = T

When the liquid undergoes expansion,

Change in Volume = ∆V = V – V0

Change in Temperature = ∆T = T – T0

It has been seen experimentally that,

∆V ∝ V0

∆V ∝ ∆T

Combining the two proportionalities, we get,

∆V ∝ V0 ∆T

∆V = (constant) V0 ∆T

The volume expansion (∆V) of the fluid can be calculated using the formula.

∆V = β V0 ∆T

Here, β is the proportionality constant and is known as the coefficient of expansion (or more accurately coefficient of volume expansion).

β = coefficient of volume expansion

Interpretation

- This formula shows that the variation in volume (∆V) is directly proportional to the original volume (V0) and the temperature variation (∆T).

- The coefficient of volume expansion (β) quantifies variation in the volume of a material per degree rise or fall in temperature.

Coefficient of Thermal Expansion (CTE)

CTE quantifies the extent to which a material expands or contracts when subjected to variation in temperature. It can be defined as “the fractional change in dimension(s) of a material per degree rise or fall in temperature.”

Example

A CTE value of 10×10−6 ℃−1 shows that the material expands by 10×10−6 times its original size for each degree Celsius rise or fall in temperature.

Unit and Symbol of CTE

The CTE is a material property and is stated in units of per degree Celsius (or Kelvin). It is typically denoted by the symbol α (alpha) for linear expansion and β (beta) for volume expansion.

Mathematical Formulation

According to the definition of CTE,

CTE = (Fraction Change in Dimension) / (Change in Temperature)

For linear expansion,

α = (∆L / L0) / (∆T)

For volume expansion,

β = (∆V / V0) / (∆T)

Significance of CTE

- The CTE is quite important in many practical applications. For instance, engineers and scientists use these values to predict how materials will perform under different temperature conditions.

- This information is essential for designing structures, machines, and systems that can resist temperature fluctuations without suffering significant deformation, stress, or failure.

Difference in CTE Values of Solids, liquids, and gases

Solids, liquids, and gases have different CTE values and thus show distinct expansion behaviours. CTE values depend on factors such as;

- crystalline structure

- chemical composition

- bonding characteristics

Solids

- CTE values are smaller in comparison to liquids and gases.

- CTE values of metals are greater than those of ceramics and polymers.

- Steel: ~11.7 × 10-6 /℃

- Ceramic: ~ 5.0 × 10-6 /℃

- Polymer: ~ 50 × 10-6 /℃

Liquids

- CTE values are larger than those of solids but smaller than those of gases.

- CTE among liquids differs based on molecular structure, intermolecular forces, and temperature.

- Water: ~ 207 × 10-6 /℃

- Alcohol: ~ 112 × 10-6 /℃

Gases

- CTE values, typically, are the largest due to high compressibility.

- CTE values in gases can vary significantly based on molecular mass, pressure, and temperature.

- Helium: ~ 3.5 × 10-3 /℃

- Carbon dioxide: ~ 8.8 × 10-3 /℃

Deduction

To put it simply,

- CTE is a fundamental property of materials that describes their response to the change in temperature.

- Solids, liquids, and gases all show go through expansion, however, they have different CTE values due to dissimilarities in their molecular structures and behaviours.

- CTE values of materials assist engineers and scientists in making informed decisions in designing and utilising various systems and structures in different temperature environments.

Effects of Thermal Expansion

In different applications and industries, thermal expansion exhibits significant impacts on solids, liquids, and gases, leading to different consequences.

Impact on Solids, Liquids, and Gases

Solids

In solids, the expansion results in dimensional change. This dimensional change causes stress, deformation, or damage to structures and components.

Example

Bridges and building materials such as concrete and steel expand or contract due to fluctuations in temperature. The expansion or contraction can lead to cracking, warping, or buckling. This can compromise the integrity and safety of the structures over time.

Liquids

In liquids, the expansion causes changes in volume and pressure. It affects the performance of systems and equipment. Additionally in industrial processes, expansion of liquids in confined spaces can result in pressure build-up and pose safety risks.

Example

For instance, in pipelines and storage tanks, temperature changes can cause liquids such as water, oil, or chemicals to expand. This can potentially exceed the capacity of the system or leaks.

Gases

In gases, the expansion causes changes in volume and pressure. It affects their behaviour and interactions with the environment.

Example

Variations in temperature in weather systems cause air masses to expand or contract. It leads to a rise or fall in atmospheric pressure and wind patterns. In industries, expansion of gases can affect the performance of pneumatic systems, combustion processes, and gas storage facilities.

Mitigation of Thermal Expansion Effects

Expansion of materials can lead to undesirable consequences such as structural damage, deformation, and stress in materials and systems. Mitigating these effects involves:

- implementing strategies to minimise or counteract the expansion of material

- incorporating design considerations to accommodate expansion

Strategies to Reduce Thermal Expansion

Material Selection

Materials with low CTE are preferred because of their lesser expansion and contraction rates.

For example, materials such as carbon fibre-reinforced composites and certain ceramics show minimal expansion compared to metals and polymers.

Composite Materials

Utilise composite materials (bimetallic strips) consisting of layers with different CTE. By strategically arranging these layers, it is possible to offset or balance the expansion effects, minimising overall dimensional changes.

Structural Design

Integrate expansion joints or flexible connections in structures to accommodate expansion and contraction. These joints allow for controlled movement without causing stress or damage to adjacent components.

Common examples include expansion joints in bridges and buildings, as well as flexible piping connections in industrial systems.

Counteracting Thermal Expansion

Mechanical Constraints

Apply mechanical restraints or constraints to limit the movement of materials experiencing expansion because of heating. By restricting expansion in specific directions or locations, it is possible to prevent deformation or damage. However, care must be taken to avoid inducing excessive stress or strain in the material.

Temperature Control

Implement temperature control procedures to stabilise the operating temperature of systems and components. This can involve actively heating or cooling materials to maintain them within a specific temperature range, thereby reducing expansion effects.

Design Considerations

Dimensional Tolerances

Design components with appropriate dimensional tolerances to account for anticipated expansion. By specifying tolerances that accommodate expected expansion and contraction, it is possible to confirm proper fit and functionality under varying temperature conditions.

Clearance Spaces

Provide sufficient clearance spaces between components to allow them to expand without interference or contact. This prevents binding, jamming, or misalignment of parts when temperatures fluctuate.

Flexible Supports

Mount and support components using flexible or spring-loaded mechanisms that can accommodate thermal movement. This allows for controlled displacement and prevents stress buildup in the material or structure.

Floating Structures

Design structures with floating or sliding connections that can move independently to compensate for expansion. This approach is commonly used in pipelines, conveyor systems, and machinery.

Deduction

Material selection, structural design, and consideration of dimensional changes are some of the factors that must be taken into account to diminish the effects of expansion because of heating. Engineers can reduce the impact of expansion and confirm the integrity and reliability of systems and structures by;

- including expansion joints

- using materials with low CTE

- designing objects with adequate clearances and flexibility

Conclusion

The expansion or contraction of materials in response to fluctuations in temperature is called thermal expansion. It is a natural phenomenon and plays a significant role in various fields, including engineering, construction, and materials science.

To address the challenges posed by expansion of materials because of heating, engineers and researchers employ various strategies. Understanding and addressing this phenomnon is crucial for ensuring the safety, reliability, and performance of systems and structures in various applications.

In conclusion, expansion because of heating is an important aspect of material behaviour that needs careful consideration and management in engineering and industry.

By establishing interdisciplinary collaboration and taking up advancements in technology, we can effectively address challenges posed by the expansion of materials because of heating and unlock new opportunities for innovation and progress.

Frequently Asked Questions (FAQs)

What is thermal expansion?

Thermal expansion can be defined as “the natural tendency of a matter to change its shape, area, and/or volume when exposed to a change in temperature.” When a material is heated, it expands, and upon cooling, it contracts.

What causes thermal expansion in solids, liquids, and gases?

When a material is heated, it experiences expansion. It happens because particles of the material gain greater kinetic energy, which leads to more forceful movement and spreading out. It is the greater particle separation that is causing this expansion.

- Solids: When heated, typically, expansion in solids happens in one dimension (linear expansion), leading to changes in length.

- Liquids: The expansion of liquids happens uniformly in 3 dimensions (volume expansion) when heated, resulting in changes in volume.

- Gases: Heating gases increase the kinetic energy of their particles and cause them to expand significantly in 3-dimensional space.

What are the consequences of thermal expansion?

It can lead to structural damage, deformation, warping, cracks, misalignments in structures and components, and stress in materials and systems.

How can thermal expansion be mitigated?

By using low CTE materials, including expansion joints, and designing with adequate clearances and flexibility, engineers can reduce the impact of expansion and confirm the integrity and reliability of systems and structures.

What are some examples of thermal expansion in everyday life?

- Expansion of metal bridges and railroad tracks in hot weather.

- Meteorological effects on wire networks and pipelines.

- Inflation of a balloon or tyre when exposed to heat.

- Rise in water level in a thermometer when heated.

How does thermal expansion impact engineering and construction?

The expansion of materials pose challenges in engineering and construction by generating dimensional changes in structures and components. It can lead to cracks, warping, and misalignments in buildings, bridges, and pipelines, compromising their integrity and safety.

How does thermal expansion affect the automotive industry?

Engine parts such as pistons and cylinder blocks expand and contract with temperature changes, impacting engine efficiency and reliability. Proper material selection and design considerations are needed to address expansion issue due to heating in automotive applications.

What are the implications of thermal expansion in aerospace engineering?

Structural components of aircraft and spacecraft experience expansion, which can affect aerodynamics, stability, and overall performance. Designing lightweight materials with tailored thermal properties is important for optimising aerospace systems.

How does thermal expansion impact composite materials?

It affects composite materials differently depending on their composition and structure. Generally, composites with dissimilar materials experience different dimensional changes due to differences in their CTE values.

Understanding these effects is essential for designing composite structures with optimal performance and durability.

What is CTE, and how is it calculated?

The coefficient of thermal expansion (CTE) is typically defined as the fractional change in length per unit temperature change, in is expressed in the units of 1/°C or 1/°F or 1/K.

It is determined as follows,

For linear expansion,

α = (∆L / L0) / (∆T)

For volume expansion,

β = (∆V / V0) / (∆T)