There are 3 classic performance metrics in physics . These are essential across various fields, from engineering to energy systems.

Table of Contents

Introduction

Understanding how different systems operate efficiently helps us optimising their performance. Mainly, 3 key performance measurement metrics are used in different systems.

Performance measurement refers to the process of evaluating how effectively a system converts input into useful output. In our daily lives, we use different machines and/or equipment that utilise different systems, and hence, they require different metrics to assess their performance accurately.

What are 3 Classic Performance Metrics in Physics ?

The 3 most common performance metrics include;

- Efficiency (

) – Common in energy and engineering applications.

) – Common in energy and engineering applications. - Mechanical Advantage (MA) – Relevant in machines and mechanical systems.

- Coefficient of Performance (COP) – Used primarily in heating and cooling systems.

1. Efficiency

It is the measure of useful output and can be defined as,

“the ratio of useful output to total input.”

It is usually expressed as a percentage. It is a crucial metric in various systems. For instance, engines, electrical circuits, and industrial processes.

Formula for

![]() is calculated using the formula:

is calculated using the formula:

![]()

Here, the quantity under consideration could be any physical quantity such as energy, power, etc. Note that ![]() .

.

Factors Affecting

- Operational conditions such as temperature, pressure, load variations, etc.

- Energy losses due to friction, heat, and resistance.

- Material properties

- Design quality

Types of

Technically, there are several types of ![]() , depending on the system being analysed. These include:

, depending on the system being analysed. These include:

- Mechanical

- Thermal

- Electrical

- Combustion

- Volumetric

(for Engines)

(for Engines)

![]() can broadly be classified into “

can broadly be classified into “![]() Energy” and “

Energy” and “![]() Power.” However, power is the rate of energy transfer, hence, it is expressed in terms of energy rather than power.

Power.” However, power is the rate of energy transfer, hence, it is expressed in terms of energy rather than power.

2. Mechanical Advantage

It is a measure of how much a machine amplifies or enhances the input force to perform work and can be defined as,

“the ratio between output force to input force.”

It is commonly used in simple machines. For instance, levers, pulleys, gears, etc.

Formula for MA

![]()

Note that good ![]() .

.

Applications of MA

- Levers: A seesaw or crowbar increases the force applied by a user.

- Pulleys: A block-and-tackle system reduces the effort needed to lift heavy objects.

- Gears: Used in bicycles and automotive transmissions to modify speed and force.

Types of MA

MA is classified into two types:

- Ideal MA: Assumes no energy loss due to friction.

- Actual MA: Accounts for real-world energy losses.

3. Coefficient of Performance (COP):

COP is used to measure energy efficiency in HVAC and can be defined as,

“the ratio between heating/cooling output to the work input.”

It is usually used in heating and cooling systems. For instance, refrigerators, air conditioners, heat pumps, etc.

Formula for COP

For cooling systems

![]()

For heating systems

![]()

Note that a good ![]() .

.

Factors Affecting COP

- External temperature conditions

- Quality of insulation in buildings

- Efficiency of compressors and refrigerants used in systems

Importance of COP

- A higher COP indicates better efficiency and lower energy consumption.

- It is used to compare different heating and cooling technologies.

- It also helps in optimising energy use in HVAC systems.

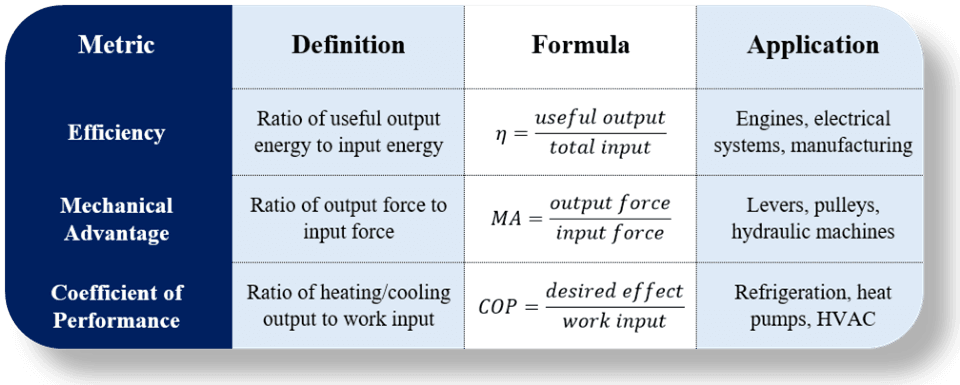

Comparing Efficiency, Mechanical Advantage, and Coefficient of Performance

Conclusion

The selection of the right performance measurement metric depends on the system being analysed. For instance;

is best for general energy conversion systems.

is best for general energy conversion systems.- MA applies to mechanical tools and machines.

- COP is essential for heating and cooling systems.

These three performance measurement methods are good tools to improve system designs. Their comprehension not only reduces energy losses but also enhances overall operational performance.

Frequently Asked Questions (FAQs)

What is performance measurement in different systems?

The process of evaluating how effectively a system converts input into useful output is called performance measurement. It helps in assessing and optimising the effectiveness and overall functionality of various systems.

What are the three key performance metrics used in different systems?

The three most common performance measurement metrics are:

- Efficiency

– Common in energy and engineering applications.

– Common in energy and engineering applications. - Mechanical Advantage (MA) – Used in machines and mechanical systems.

- Coefficient of Performance (COP) – Used in heating and cooling systems.

How is  calculated?

calculated?

![]() is calculated using the formula:

is calculated using the formula:

![]()

It is typically expressed as a percentage and represents how well a system converts input energy into useful output.

What factors affect  in different systems?

in different systems?

- Energy losses due to friction, heat, and resistance.

- Material properties and design quality.

- Operational conditions.

What is MA and how is it measured?

MA is the ratio of output force to input force:

![]()

It indicates how much a machine amplifies the applied force, making tasks easier.

What are the two types of MA?

- Ideal MA: Assumes no energy loss due to friction.

- Actual MA: Considers real-world energy losses such as friction and resistance.

What are some practical applications of MA?

- Levers: Crowbars and seesaws increase applied force.

- Pulleys: Reduce the effort needed to lift heavy loads.

- Gears: Used in bicycles and vehicles to adjust speed and torque.

What is the COP and how is it measured?

COP is the ratio of heating/cooling output to work input. It is calculated as:

- For cooling systems:

![]()

- For heating systems:

![]()

Why is COP important in heating and cooling systems?

- It optimises energy use in HVAC (Heating, Ventilation, and Air Conditioning) systems.

- A higher COP indicates better efficiency and lower energy consumption.

- Helps compare different heating and cooling technologies.

How do you choose the right performance measurement metric for a system?

- Use

for energy conversion systems like power plants and motors.

for energy conversion systems like power plants and motors. - Use MA for mechanical tools such as levers and pulleys.

- Use COP for heating and cooling systems like air conditioners and heat pumps.